David Kleiner on How COVID Has Accelerated AR at Toyota

As the world’s second-largest automaker and tenth largest corporation, Toyota needs no introduction. Among Toyota’s nearly 365,000 employees is David Kleiner, Extended Reality Lab Manager. Working from Toyota North America’s headquarters campus in Plano, Texas, Mr. Kleiner was an early champion of using AR for marketing use cases at Toyota. We spoke recently to learn more about his work.

AREA: Tell us about your background in AR at Toyota.

Kleiner: I started almost three years ago. I was working at our headquarters, so my interest in AR was more around marketing and sales than engineering and design. I was convinced that AR was going to be the next big thing in marketing and I wanted Toyota to get ahead of the market.

We made a couple of prototypes that never made it past the prototype stage but got some good reviews. Then COVID hit and everyone was saying, “We’re in a touchless society now; how do we sell?” Well, this is how you sell. As a result, what was a part-time hobby job for me is now full-time. What I’m trying to solve now is how XR fits in at every stage of the customer journey. We’re trying to educate brand-loyal customers that we’re cutting edge and that there are some Toyota vehicles coming out that you can experience at home without visiting a dealership. We’re then trying to track that through to a sale.

A lot of this is about customer education. They don’t know, for example, how Toyota Safety Sense works. They don’t know all the features we put into the vehicle. So our goal is to educate them and “wow” them at the same time – which we hope leads to a sale. Once the sale is made, how do we do the “care and feeding” afterwards? We already have a prototype of an AR owner’s manual, which went over really well – and also reduces costs because there’s no printing required. On our first project, the Lexus AR Kit, we found we could save $11 million a year on shipping and handling of owner’s manuals.

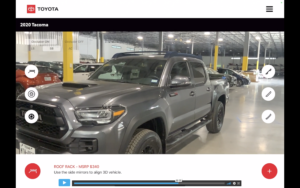

Once we’ve made the sale and delivered the owner’s manual, the next step is selling accessories – and that’s the other product I’m working on right now. We want to be able to capture the buyer’s car – not a cartoon, but a real image – and fly in some accessories to show them how they can customize their vehicle to look better and perform better.

That’s where we’re going. We’re trying to follow the full customer lifecycle.

Our first proof of concept, as I mentioned, was the Lexus AR Kit. It started out as a training platform for dealership personnel but then we modified it to train people on how to use their vehicles. The second pilot we did was a Virtual Showroom. Users can plop the car down at scale in their driveways, then approach it and look inside the vehicle without having to go to the dealership. We completed that in mid-September. The third pilot we’re working on is for accessory sales. The target product is the Tacoma, our smaller pickup truck, which is the most customized of our vehicles. We believe we can increase Tacoma accessory sales by $5 million. If that’s successful, we’ll roll it out to our other highly-customized vehicles.

I’m also tangentially involved in some training work at our manufacturing plants. Since people can’t come to a classroom anymore because of the pandemic, we’re training them remotely using HoloLens through our partnership with Microsoft. Some of the early results are just phenomenal. We found that we could take training from 13 days down to two days. Retention is better and quality is up. It’s been great for both new hires and for reskilling existing workers to take on new tasks.

AREA: What AR software and tools are you using?

Kleiner: On the training side, it’s all Microsoft HoloLens. For marketing and sales, we don’t have an AR studio, so we’re working with an outside vendor called Groove Jones and it’s all custom.

AREA: Tell us about your experience trying to champion this technology in a corporate setting.

Kleiner: I spent a lot of time trying to educate folks, telling them this is not a toy, this is a true tool that belongs in the enterprise and should be part of the customer experience. And many people basically said, “That’s nice, but we’re going to keep doing things as we have.” Once COVID hit, those same people realized we couldn’t keep doing things the way we always had. I’m in demand now!

AREA: So what’s next for you?

Kleiner: Right now, we’re focused on bringing these current proofs of concept to fruition. If those work out well, we’ll expand to other projects. The AR approach is ideal for demonstrating things that aren’t clear in the owner’s manual – for example, how to install an infant seat in the car. That’ll probably be in the next iteration of the AR owner’s manual project.