Using Augmented Reality For Hands-On Training

What are the benefits?

Augmented reality provides many benefits for educating and training employees. Visual and hands-on learners may learn more from augmented reality than from a lecture or conference. They can practice as many times as needed without dangerous consequences. In addition, trainees can learn in an interactive environment and feel more inclined to engage.

Employees may feel more willing to work hard if they can sense what they need to learn. AR training provides many training opportunities for them to practice until they perfect their skills. Furthermore, they can complete the training almost anywhere that they can use their AR device.

You can reduce the time trainees spend working with experts. Instead of working directly with clients, they can practice until they feel confident enough to handle the situation in person. In that sense, AR also improves the customer experience. They are more likely to interact with a fully-trained employee, so customer service may run smoother and faster.

Lastly, AR training can decrease training costs. While the equipment is a pricey investment, you can reuse it for all of your trainees. Additionally, most people have smartphones that work with AR training apps.

How do I get started with augmented reality?

If you’re a business leader in an innovation role and are looking at ways to adopt AR in a useful and productive way, there are many considerations to keep in mind when adopting the technology. First, identify the specific use case for AR. There are several ways to implement AR, and each has its merits.

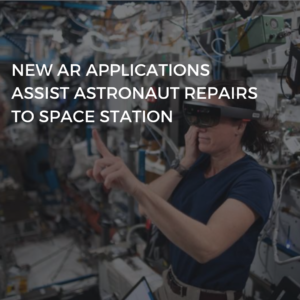

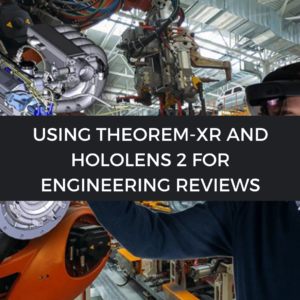

In my opinion, the best-suited option for training is wearable AR. This is where the user’s hands are free as they wear an augmented viewpoint headset. The two main players in this segment are the Microsoft HoloLens or the RealWear HMT-1. Both headsets allow a full range of motion and give the user overlaid information in real-time to assist them during complex tasks or procedures.

Consider your training needs to determine the best solution. Do you need a large field of view (FOV) or the ability to move around easily? Do you want graphical overlays or textual ones? Would it be helpful for trainees to pull data from schematics or instructions and have that information relayed to their eye in AR order to work hands-free? Or do you want them to see an augmented overlay of information in the real world to aid whatever job or task they are training on?

In my experience, the HoloLens is better suited for complex visualizations and works well where there’s a need for high-fidelity graphical overlays. On the flip side, the RealWear HMT-1 is more of an informational diegesis that will aid the worker by supplying additional context, voiceovers, manuals or even diagrams all within a small picture-in-picture viewpoint.

Augmented reality can help employers accelerate training time, educate employees and enhance the workforce by keeping skills relevant. While it is costly to implement, AR can save time and money in the long run because of its efficiency and effectiveness. As more companies integrate AR training into their employment strategies, consider how you can apply it to your business.

When looking to adopt the technology, first consider the use case and then decide on the hardware that would best fit the specific job you are looking to train for. Do your research to build a business case internally to help make a more informed decision.